For Product and Pricing Information

TB2150R Excavator | 15.6-16.2 Tonne

The New TB2150R is the largest excavator in the Takeuchi line-up. It features a fixed conventional boom combined with reduced tail swing, with 85kW of power performance . Regarded as a high specification machine with plenty of value-added features, owner operators really appreciate the power, performance and reliability of the TB2150R.

Product Details

Features

| OPERATOR STATION |

|---|

| Cab ( ROPS / TOPS/ OPG) |

| Wrap Around Counterweight |

| Large Interactive 7" Multi-Information Colour Display |

| Rear and Blind-side Wide-angle Colour Cameras with Auto-reverse Activation Display Split Screen |

| Fully Adjustable Deluxe HighBack Heated Air Suspension Seat |

| Adjustable Arm Rests & Heated Drinks Holder |

| Air Con with Climate Control System |

| Digital Radio - AM/FM/MP3 Radio/Aux-in/USB/Bluetooth with Stereo Speakers |

| Multi Vent Heater / De-mister |

| Gas Lift-Assist Retractable Front Window, Removable Lower Front Window In-Cab Storage, Twin Sliding (50-50) Door Glass |

| Front Window Guard (optional) |

| Cab Mirror - 5 Blindspot Mirrors |

| Roof Guard and Steel Rain Guard |

| Anti-slip Service Access Steps with Handrail |

| Large Fully Supporting Foot Travel Pedals |

| Dual Foot Rests |

| ELECTRICAL |

| Sealed Rocker Switches |

| Engine Shut-down Switch |

| 24 Volt System / Twin Batteries |

| 3x In-Cab Power Sockets 12V/24V/USB |

| Front of Cab External Power Socket - 24V |

| Switched Roof Beacon Power Socket - 24V |

| 6 x Hi-Visibility LED Workzone Lighting 2 x Cab Roof, 2x Boom, 1x Side Cover and 1x Cab Rood Rear |

| Travel Alarm & Horn |

| TFM (Takeuchi Fleet Management) |

| TSS (Takeuchi Security System Immobilizer) |

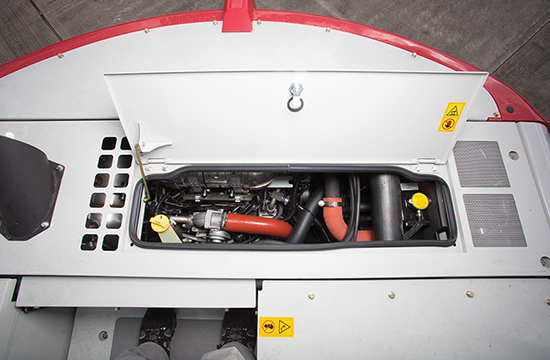

| ENGINE |

| Stage V Ready - Low Emissions - SCR - DPF - AdBlue |

| High Pressure Common Rail Fuel Injection |

| Automatic Fuel Bleed System |

| Steel Lockable Fuel Filler Cap |

| Dual Fuel Filtration with Water Trap Sensor |

| Dual Element Air Filter |

| High Capacity Radiator |

| AdBlue Tank with Audible Refill Level Alarm |

| Dial Throttle Control with Automatic Idle |

| Working Modes: Standard, ECO and High Altitude |

| Electric Refuelling Pump with Extended Length Suction Hose |

| Service Interval - 500 hours |

| HYDRAULIC & WORKING EQUIPMENT |

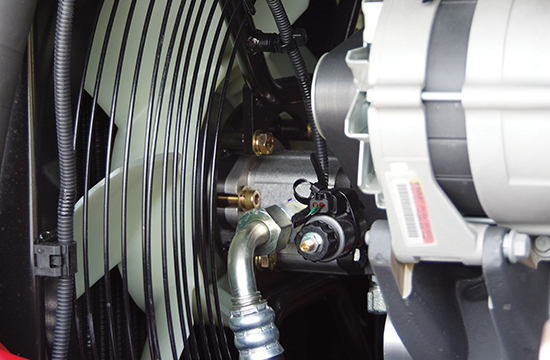

| Hydraulic Pilot Controls with Pilot Accumulator |

| Cushioned Dual Boom Cylinders, Cushioned Arm Cylinder |

| Dual Boom and Single Arm Cylinder Holding Check Valves |

| Automatic Slew Brake |

| Lift Overload Alarm |

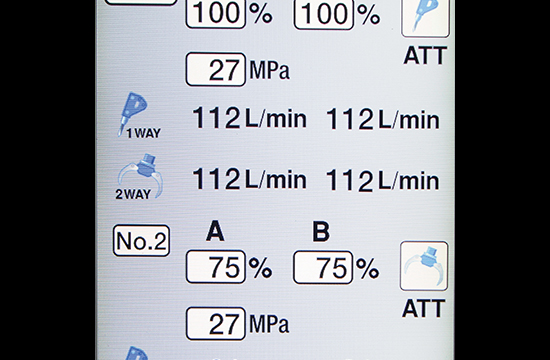

| Auxiliary Flows and Pressure Adjustable from Control Panel |

| Multiple Attachment Presets / Password Protected Aux Settings |

| 1,2,3 Aux Standard, 3rd Aux Pre-piped with Hitch Pipework, 4th Aux Optional |

| Proportional Auxiliary Controls with Detent |

| Primary Auxiliary Circuit with Auto Tank and Pressure Release |

| Switched 1/2-Way Aux Flow |

| Auxiliary Hydraulics with Independent Isolation Valves |

| Large Hydraulic Reservoir with Fluid Level Sight Gauge |

| High Capacity Hydraulic Oil Cooler |

| UNDERCARRIAGE AND FRAME |

| Compact Tail Swing - (Exceeds only 35cm on 700mm steel track) |

| Steel Tracks 700mm Standard |

| Rubber Tracks Optional |

| Heavy Duty Dozer Blade |

| Twin Heavy Duty Dozer Cylinders |

| Ground Level Hydraulic Hoses with Steel Spiral Wrap Protection |

| Automatic Load Sensing 2 Speed Travel |

| Maintenance-free Triple Flanged Sealed Bearing Track Rollers and Dual Carrier Rollers |

| Easy Tension Grease Filled Track Adjusters |

| Safe Anti-Slip Boarding Steps - Carriage Mounted |

| Lower Carriage and Blade Tie Down Points |

Specifications

| ENGINE | |

|---|---|

| Make | DEUTZ |

| Model | TCD3 6L4 |

| Rated Output (kW)/RPM | 85/2000 |

| Maximum Torque (Nm) | 460 |

| Cylinders | 4 |

| Displacement (cc) | 3621 |

| Electrical System | 24 volt 90 Amp |

| DIMENSIONS & WEIGHT | |

| Machine weight incl fuel/hitch/bkt Long (kg) | 15710 |

| Machine weight incl fuel/hitch/bkt 2-piece (kg) | 16270 |

| Length (Transporting) Long (mm) | 7405 |

| Length (Transporting) 2-piece (mm) | 7785 |

| Width (mm) | 2690 |

| Height (mm) Transporting (2-piece) | 3190 (2950) |

| Ground Clearance (mm) | 445 |

| Dozer Blade (W x H) (mm) | 2690 x 550 |

| Front Swing Radius Long / (2-piece) (mm) | 2610 (2590) |

| Slew Radius (mm) | 1700 |

| HYDRAULIC SYSTEM | |

| Main System Pressure (bar) | 340 |

| Pump Type | Variable Displacement |

| 1st Aux Max Flow (l/min) | 224 |

| 1st Aux Max Pressure (bar) Variable | 270 |

| 2nd Aux Max Flow (l/min) | 55 |

| 2nd Aux Flow Pressure (bar) Variable | 230 |

| Standard Aux | 1st 2nd & 3rd |

| Optional Aux | 4th |

| 3rd Aux | Used for Hitch |

| SWING SYSTEM | |

| Slew Speed (rpm) | 11 |

| Slew Motor | Piston |

| Slew Brake | Disc |

| UNDERCARRIAGE | |

| Traction Motor | Variable Displacement |

| Traction Drive | Epicyclic Gearing |

| Traction Brake | Disc |

| Track Width (mm) | 700 |

| Ground Contact Length (mm) | 3045 |

| Ground Pressure (kpa) | 46.2 (48.1) |

| Maximum Gradeability | 35° |

| CAPACITIES | |

| Hydraulic System (l) | 235 |

| Fuel Tank (l) | 221 |

| Engine Lubrication (l) | 10 |

| Cooling System (l) | 27 |

| HEALTH AND SAFETY | |

| Noise Level Sound Power Level (LwA) | 99 dB |

| Vibration Hand Arm / Body m/sec² | ≤2.5 / ≤0.5 |

| OPTIONS | |

| Hydraulic Breaker | TKB802-S, |

| Hitch | Hydraulic Quick Hitch. |

Operating Dimensions

| OPERATING PARAMETERS | |

|---|---|

| Max Digging Depth Long Arm (mm) | 6060 |

| Max Digging Depth 2-Piece (mm) | 5750 |

| Max Dump Height Long Arm (mm) | 7140 |

| Max Dump Height 2-Piece (mm) | 7460 |

| Max Reach at Ground Level Long Arm (mm) | 8665 |

| Max Reach at Ground Level 2-Piece (mm) | 8730 |

| Max Vertical Digging Depth Long Arm (mm) | 5545 |

| Max Vertical Digging Depth (2-Piece) (mm) | 5160 |

| Max Bucket Digging Force (kN) | 96.3 |

| Max Arm Digging Force (kN) | 60 |

| Travel Speed (km/h) | 2.7 / 5.1 |

Lifting Diagram

TB2150R Compact Excavator Lifting Diagram – Mono – Long Arm

TB2150R Long arm chart with & without dozer blade 514800502~TB2150R Compact Excavator Lifting Diagram – Mono – 2-piece

TB2150R-2-Pc-Boom

TB2150R Compact Excavator Lifting Diagram

TB2150R Compact Excavator Lifting Diagram -Mono – Middle Arm

TB2150R cab amended 2022Takeuchi Fleet Management (TFM)

TFM is installed on all Takeuchi machines above 4-tonnes, TFM is optional on machines under 4-tonnes.

TFM is installed on all Takeuchi machines above 4-tonnes, TFM is optional on machines under 4-tonnes.

TFM is a remote Telematics monitoring tool that utilises machine data to better manage your fleet, and to keep costs down by being alerted to machine performance and health.

TFM remotely connects users to their Takeuchi equipment by providing alerts and machine information including location, utilisation, performance, and maintenance data to give insights into where and how equipment is being operated.

Takeuchi is providing TFM free of charge during the initial warranty period. For continued Telematics support for your Takeuchi machines, customers can extend the TFM cover via the local Takeuchi dealership.

TSS - Takeuchi Security System

Takeuchi security system as standard.

- Only programmed keys for start-up

- Un-programmed keys alert operator via VDU and alarm

- Includes 1 red master and 3 black user keys (programme up to 13 user keys)